In the world of digital imaging, few technical factors influence image quality as much as the type of electronic shutter in your sensor. Whether you’re shooting high-speed industrial processes, filming cinematic sequences, or capturing faint astronomical phenomena, the shutter technology inside your CMOS camera plays a critical role in how your final image turns out.

Two dominant types of CMOS electronic shutters, global shutters and rolling shutters, take very different approaches to exposing and reading out light from a sensor. Understanding their differences, strengths, and trade-offs is essential if you want to match your imaging system to your application.

This article will explain what CMOS electronic shutters are, how global and rolling shutters work, how they perform in real-world situations, and how to decide which is best for you.

What Are CMOS Electronic Shutters?

A CMOS sensor is the heart of most modern cameras. It’s responsible for converting incoming light into electrical signals that can be processed into an image. The "shutter" in a CMOS camera isn’t necessarily a mechanical curtain—many modern designs rely on an electronic shutter that controls how and when pixels capture light.

Unlike a mechanical shutter that physically blocks light, an electronic shutter works by starting and stopping the flow of charge within each pixel. In CMOS imaging, there are two primary electronic shutter architectures: global shutter and rolling shutter.

Why does distinction matter? Because the method of exposure and readout directly affects:

● Motion rendering and distortion

● Image sharpness

● Low-light sensitivity

● Frame rate and latency

● Overall suitability for different types of photography, video, and scientific imaging

Understanding Global Shutter

GMAX3405 Global Shutter Sensor

|

|

|

|

|

|

|

How Global Shutter Works

CMOS Global shutter cameras begin and end their exposure simultaneously across the entire sensor. This is achieved using 5 or more transistors per pixel, and a 'storagenode' that holds acquired photoelectron charges during readout. The sequence of an exposure is as follows:

1. Begin exposure simultaneously in each pixel by clearing acquired charges to ground.

2. Wait for the chosen exposure time.

3. At the end of exposure, move acquired charges to the storage node in each pixel, ending exposure of that frame.

4. Row by row, move electrons into the pixel's readout capacitor, and relay the accumulated voltage to the readout architecture, culminating in the analogue-to-digital converters (ADCs). The next exposure can typically be performed simultaneously with this step.

Advantages of Global Shutter

● No Motion Distortion – Moving subjects retain their shape and geometry without the skew or wobble that can occur with sequential readout.

● High-Speed Capture – Ideal for freezing motion in fast-moving scenes, such as in sports, robotics, or manufacturing quality control.

● Low Latency – All image data is available at once, enabling precise synchronization with external events, such as laser pulses or strobe lights.

Limitations of Global Shutter

● Lower Light Sensitivity – Some global shutter pixel designs sacrifice light-gathering efficiency to accommodate the circuitry needed for simultaneous exposure.

● Higher Cost & Complexity – Fabrication is more challenging, often resulting in higher prices compared to rolling shutter counterparts.

● Potential for Increased Noise – Depending on sensor design, the extra electronics per pixel can lead to slightly higher read noise.

Understanding Rolling Shutter

How Rolling Shutter Works

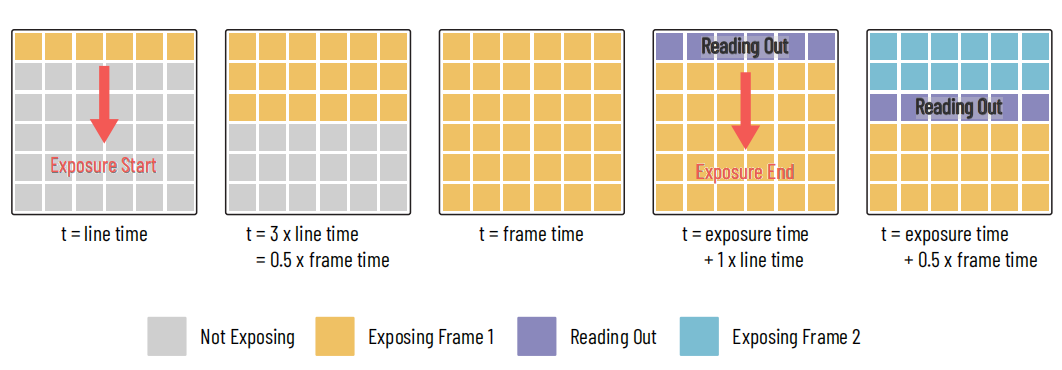

Using only 4 transistors and no storage node, this simpler form of CMOS pixel design leads to a more complicated electronic shutter operation. Rolling shutter pixels start and stop the exposure of the sensor one row at a time, 'rolling' down the sensor. The sequence opposite (also shown in the figure) is followed for each exposure:

Rolling shutter process for a 6x6 pixel camera sensor

The first frame begins exposure (yellow) at the top of the sensor, sweeping downwards at a rate of one line per line time. Once exposure has completed for the top line, the read out (purple) followed by the start of the next exposure (blue) sweep down the sensor.

1. Begin exposure to the top row of the sensor by clearing acquired charges to

ground.

2. After the 'row time' is elapsed, move to the second row of the sensor and begin exposure, repeating down the sensor.

3. Once the requested exposure time has finished for the top row, end the exposure by sending acquired charges through the readout architecture. The time taken to do this is the 'row time'.

4. As soon as readout is completed for a row, it is ready to begin exposure again from Step 1, even if that means overlapping with other rows performing the previous exposure.

Advantages of Rolling Shutter

● Better Low-Light Performance – The pixel designs can prioritize light collection, improving signal-to-noise ratio in dim conditions.

● Higher Dynamic Range – Sequential readout designs can handle brighter highlights and darker shadows more gracefully.

● More Affordable – Rolling shutter CMOS sensors are more common and cost-effective to manufacture.

Limitations of Rolling Shutter

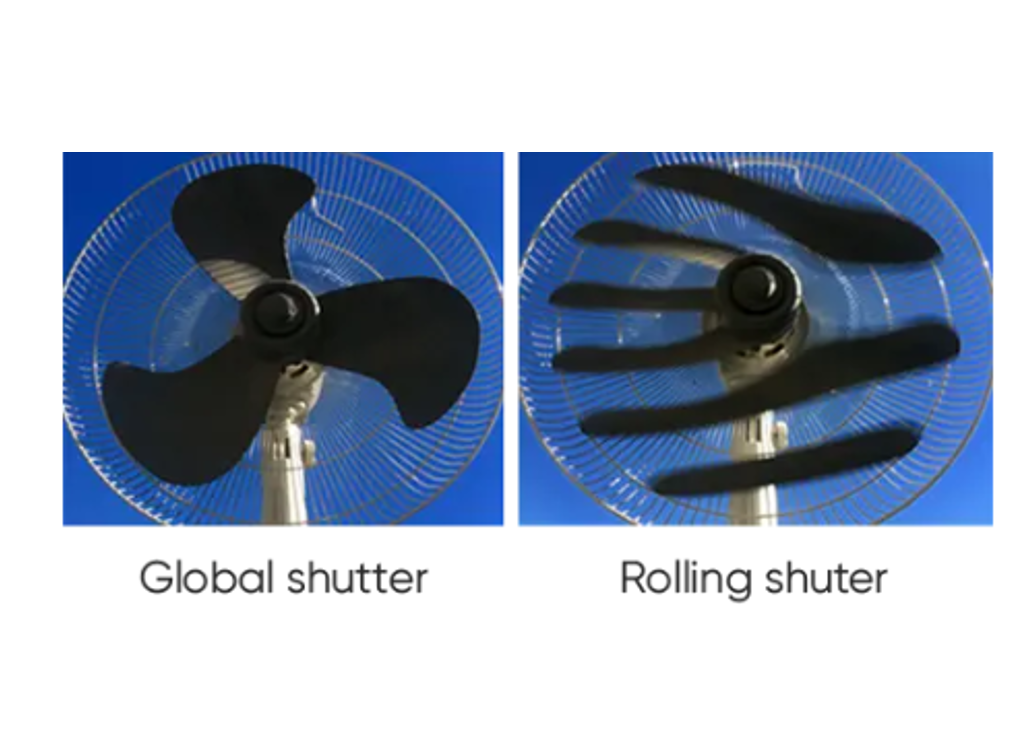

● Motion Artifacts – Fast-moving subjects may appear skewed or bent, known as the “rolling shutter effect.”

● Jello Effect in Video – Handheld footage with vibration or quick panning can cause wobbling in the image.

● Synchronization Challenges – Less ideal for applications requiring precise timing with external events.

Global vs. Rolling Shutter: Side-by-Side Comparison

Here’s a high-level view of how rolling and global shutters compare:

|

Feature |

Rolling Shutter |

Global Shutter |

|

Pixel Design |

4-transistor (4T), no storage node |

5+ transistors, includes storage node |

|

Light Sensitivity |

Higher fill factor, easily adapted to back-illuminated format → higher QE |

Lower fill factor, BSI more complex |

|

Noise Performance |

Generally lower read noise |

Can have slightly higher noise due to added circuitry |

|

Motion Distortion |

Possible (skew, wobble, jello effect) |

None — all pixels exposed simultaneously |

|

Speed Potential |

Can overlap exposures and read multiple rows; often faster in some designs |

Limited by full-frame readout, though split readout can help |

|

Cost |

Lower manufacturing cost |

Higher manufacturing cost |

|

Best Use Cases |

Low-light imaging, cinematography, general photography |

High-speed motion capture, industrial inspection, precision metrology |

Core Performance Differences

Rolling shutter pixels typically use a 4-transistor (4T) design without a storage node, while global shutters require 5 or more transistors per pixel plus additional circuitry to store photoelectrons before readout.

● Fill Factor & Sensitivity – The simpler 4T architecture allows a higher pixel fill factor, meaning more of each pixel’s surface is dedicated to light collection. This design, combined with the fact that rolling shutter sensors can be adapted more easily to a back-illuminated format, often results in higher quantum efficiency.

● Noise Performance – Fewer transistors and less complex circuitry generally mean rolling shutters exhibit lower read noise, making them better suited to low-light applications.

● Speed Potential – Rolling shutters can be faster in certain architectures because they allow overlapping exposure and readout, though this is highly dependent on sensor design and readout electronics.

● Cost & Manufacturing – The simplicity of rolling shutter pixels typically translates to lower production costs compared to global shutters.

Advanced Considerations and Techniques

Pseudo-Global Shutter

In situations where you can precisely control when light reaches the sensor—such as using an LED or laser light source triggered by hardware—you can achieve “global-like” results with a rolling shutter. This pseudo-global shutter method synchronizes the illumination with the exposure window, minimizing motion artifacts without requiring a true global shutter design.

Image Overlap

Rolling shutter sensors can begin exposing the next frame before the current frame’s readout is complete. This overlapping exposure improves duty cycle and is beneficial for high-speed applications where capturing the maximum number of frames per second is critical, but can complicate timing-sensitive experiments.

Multiple Row Readout

Many high-speed CMOS cameras can read more than one row of pixels at a time. In some modes, rows are read in pairs; in advanced designs, up to four rows can be read simultaneously, effectively reducing total frame readout time.

Split Sensor Architecture

Both rolling and global shutters can use a split sensor layout, where the image sensor is divided vertically into two halves, each with its own row of ADCs.

● In rolling shutter split sensors, readout often begins from the center and rolls outward toward both the top and bottom, further reducing latency.

● In global shutter designs, split readout can improve frame rates without altering exposure simultaneity.

How to Choose for Your Application: Rolling or Global Shutter?

The global shutter may benefit applications

● Require high-precision timing of events

● Require very short exposure times

● Require sub-millisecond delay before the start of an acquisition to synchronize with an event

● Capture large-scale motion or dynamics on a similar or faster timescale to a rolling shutter

● Require simultaneous acquisition across the sensor, but cannot control light sources to use pseudo-global shutter across a large area

The rolling shutter may benefit applications

● Challenging low-light applications: The additional quantum efficiency and lower noise of rolling shutter cameras often lead to improved SNR

● High-speed applications where exact simultaneity across the sensor is not important, or the delay is small compared to experimental timescales

● Other more general applications where the manufacturing simplicity and lower cost of rolling shutter cameras are beneficial

Common Misconceptions

1. "Rolling shutter is always bad."

Not true—rolling shutters are ideal for many use cases and often outperform global shutters in low light and dynamic range.

2. "Global shutter is always better."

While distortion-free capture is an advantage, the trade-offs in cost, noise, and sensitivity may outweigh the benefits of slower-paced imaging.

3. "You can’t shoot video with a rolling shutter."

Many high-end cinema cameras use rolling shutters effectively; careful shooting techniques can minimize artifacts.

4. "Global shutters eliminate all motion blur."

They prevent geometric distortion, but motion blur from long exposure times can still occur.

Conclusion

The choice between global and rolling shutter technology in a CMOS camera boils down to the balance between motion handling, light sensitivity, cost, and your specific application needs.

● If you need distortion-free capture for fast-moving scenes, global shutter is the clear choice.

● If you prioritize low-light performance, dynamic range, and budget, the rolling shutter often delivers the best results.

Understanding these differences ensures you can select the right tool—whether it’s for scientific imaging, industrial monitoring, or creative production.

FAQs

Which shutter type is better for aerial photography or drone mapping?

For mapping, surveying, and inspection where geometric accuracy is crucial, a global shutter is preferred to avoid distortion. However, for creative aerial video, a rolling shutter can still deliver excellent results if movements are controlled.

How does shutter choice impact low-light imaging?

Rolling shutters generally have an advantage in low-light performance because their pixel designs can prioritize light-gathering efficiency. Global shutters may require more complex circuitry that can slightly reduce sensitivity, although modern designs are closing this gap.

How does shutter type affect a scientific camera?

In high-speed scientific imaging—such as particle tracking, cell dynamics, or ballistics—a global shutter is often essential to avoid motion distortion. But for low-light fluorescence microscopy, an sCMOS camera with a rolling shutter may be chosen to maximize sensitivity and dynamic range.

Which is better for industrial inspection?

In most industrial inspection tasks—especially those involving moving conveyor belts, robotics, or machine vision—a global shutter is the safer choice to ensure precise measurements without motion-induced geometric errors.

Tucsen Photonics Co., Ltd. All rights reserved. When citing, please acknowledge the source: www.tucsen.com

2025/09/30

2025/09/30