Line scan cameras are specialized imaging devices designed to capture high-resolution images of moving or continuous objects. Unlike traditional area scan cameras that capture a 2D image in a single exposure, line scan cameras build images line by line—ideal for applications like web inspection, semiconductor analysis, and packaging verification.

These cameras typically feature a single row of pixels (or sometimes multiple rows), and when combined with a moving subject or scanning system, they can produce high-quality 2D images of objects of virtually any length. Depending on the sensor type, line scan cameras typically use either CCD or CMOS sensor technology—similar to what’s found in many CMOS cameras—with CMOS becoming the preferred choice due to its speed and energy efficiency.

What Is a Line Scan Camera?

Line scan cameras are typically optimized for industrial rather than scientific use, and may have limitations in low-light or ultra-high-precision applications. High readout noise, small pixels and generally low quantum efficiency can mean that these cameras require high light levels to deliver a workable SNR.

Line scan cameras can be used in two primary ways:

1-Dimensional Capture

One-dimensional information can be captured, such as in spectroscopy applications. Results are often represented in graph form in camera software, with intensity on the y-axis versus camera pixel on the x-axis.

2-Dimensional Capture

The camera can be 'scanned' across an imaging subject, through either moving the camera or the imaging subject, and a 2-dimensional image can be formed by capturing successive 1-dimensional slices.

This form of imaging allows the capture of arbitrarily large images in the scan dimension. The ability to capture subjects on the move without motion blur (or rolling shutter artefacts) means that line scan cameras are very commonly used in industrial applications, for assembly lines, inspection of large imaging subjects, and more.

How Does a Line Scan Camera Work?

A line scan camera works in coordination with a moving object or scanning mechanism. As the object passes beneath the camera, each line of the image is captured sequentially in time. These lines are then combined in real-time or via software to produce a full 2D image.

Key components include:

● 1-Dimensional sensor: Typically a single row of pixels.

● Motion control: A conveyor or rotating mechanism ensures even movement.

● Lighting: Often line or coaxial lighting for consistent illumination.

Because the image is built line by line, synchronization is critical. If the object moves inconsistently or the timing is off, image distortion can occur.

Line Scan vs. Area Scan Cameras

|

Feature |

Line Scan Camera |

Area Scan Camera |

|

Image Capture |

One line at a time |

Full 2D frame at once |

|

Ideal Use |

Moving or continuous objects |

Stationary or snapshot scenes |

|

Image Size |

Virtually unlimited in length |

Limited by sensor size |

|

Integration |

Requires motion and timing control |

Simpler setup |

|

Typical Applications |

Web inspection, printing, textiles |

Barcode scanning, robotics, general imaging |

In short, line scan cameras excel when imaging fast-moving or very large objects. Area scan cameras are better suited for applications with static or small targets.

Key Features of Line Scan Cameras

When choosing a line scan camera, consider the following specifications:

● Resolution: Number of pixels per line, impacting detail level.

● Line Rate (Hz): Number of lines captured per second—vital for high-speed inspections.

● Sensor Type: CMOS (fast, low power) vs. CCD (higher image quality in some cases).

● Interface: Data transfer options like GigE, Camera Link, or CoaXPress.

● Dynamic Range & Sensitivity: Important for inspecting objects with variable brightness or reflectivity.

● Color vs. Monochrome: Color cameras use multiple rows with RGB filters; monochrome may offer higher sensitivity.

Pros and Cons of Line Scan Cameras

Pros

-

Can capture 1-dimensional information at very high speed (typically measured in 100s of kHz line rate). Can capture 2-dimensional images of arbitrary size at high speed when scanning across an imaging subject.

-

Can capture color information without sacrificing resolution through the use of separate red-, green- and blue- filtered rows, or custom cameras can offer specific wavelength filtering.

-

Illumination only needs to be 1-dimensional and, depending upon imaging setup, can require no flat-field or other corrections in the second (scanned) dimension.

Cons

-

Require specialist hardware & software setups to acquire 2-dimensional data.

-

Typically not well suited to low-light imaging due to low QE, high noise and small pixel sizes, especially combined with the short exposure times typical of high-speed scanning.

-

Not usually intended for scientific imaging, so linearity and image quality may be poor.

Common Applications of Line Scan Cameras in the Scientific Field

Line scan cameras are widely used in scientific research and advanced imaging applications that demand high resolution, precision, and continuous data acquisition. Typical uses include:

● Microscopy Imaging: Capturing high-resolution line scans for detailed surface or cellular analysis.

● Spectroscopy: Recording spectral data across samples with precise spatial resolution.

● Astronomy: Imaging of celestial objects or tracking fast-moving targets with minimal distortion.

● Materials Science: Surface inspection and defect detection in metals, polymers, or composites.

● Biomedical Imaging: Scanning biological tissues for diagnostic or research purposes, including histology and pathology.

These applications benefit from the line scan camera’s ability to generate highly detailed, distortion-free images over extended areas or in dynamic experimental setups.

Limitations of Line Scan Cameras

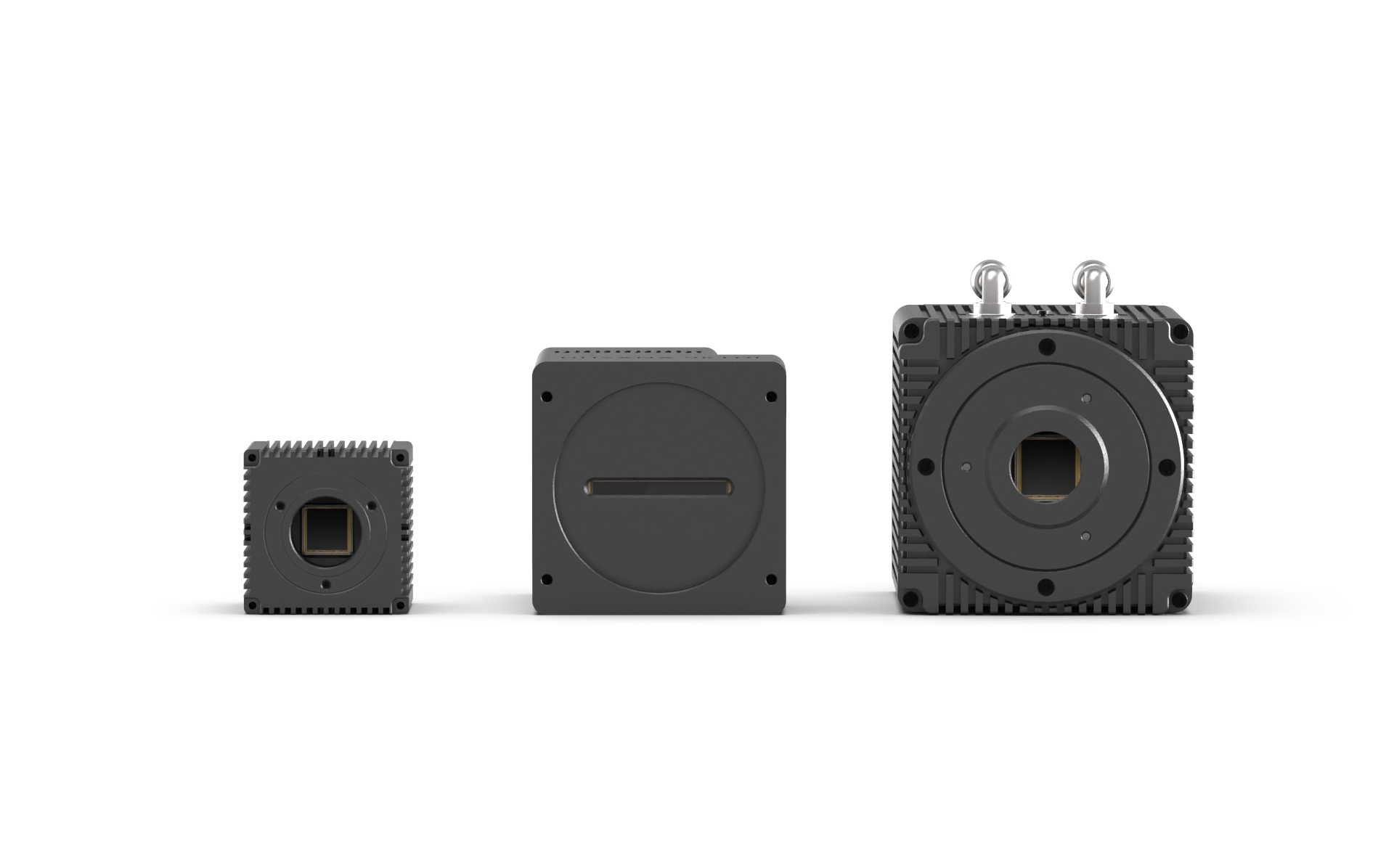

Schematic Diagram: Tucsen High-Sensitivity Line Scan/TDI Scientific Camera

Left: Uncooled Area Scan Camera

Middle: TDI Scientific Camera

Right: Cooled Area Scan Camera

While line scan cameras offer excellent resolution and are well-suited for continuous imaging, they do have limitations, particularly in advanced scientific environments where sensitivity and signal stability are critical.

One major limitation is their performance in low-light conditions. Traditional line scan cameras rely on single-pass exposure, which may not provide sufficient signal-to-noise ratio (SNR) when imaging weakly illuminated or light-sensitive samples, such as in fluorescence microscopy or certain biomedical assays. Additionally, achieving accurate synchronization between object motion and image acquisition can be technically demanding, especially in setups involving variable speed or vibration.

Another constraint is their limited ability to capture high-quality images of very slow-moving or unevenly illuminated specimens, which may result in inconsistent exposure or motion artifacts.

To overcome these challenges, TDI (Time Delay Integration) cameras have emerged as a powerful alternative. By accumulating signal across multiple exposures as the object moves, TDI cameras significantly enhance sensitivity and image quality, making them especially valuable in scientific fields requiring ultra-low-light imaging, high dynamic range, or precise temporal resolution.

Conclusion

Line scan cameras are indispensable tools in industries that demand high-speed, high-resolution imaging of moving or continuous surfaces. Their unique scanning method offers distinct advantages over area scan cameras in the right scenarios, especially for applications like web inspection, semiconductor imaging, and automated packaging.

While line scan cameras are primarily used in industrial settings, users requiring high sensitivity or low-light performance may benefit from exploring scientific cameras designed for precision imaging applications.

Understanding how line scan cameras work and what to look for when selecting one will help you design smarter, more reliable inspection systems.

FAQs

How does a line scan camera capture color images?

Color line scan cameras typically use tri-linear sensors, which contain three parallel lines of pixels, each with a red, green, or blue filter. As the object moves past the sensor, each color line captures its respective channel in sequence. These are then combined to form a full-color image. Precise synchronization is essential to avoid color misalignment, especially at high speeds.

How to Choose the Right Line Scan Camera

Selecting the right camera depends on your application’s requirements. Here are some key factors to consider:

● Speed Requirements: Determine your line rate needs based on object speed.

● Resolution Needs: Match the resolution to your inspection tolerances.

● Lighting and Environment: Consider special lighting for reflective or dark surfaces.

● Sensor Type: CMOS has become mainstream for its speed and efficiency, while CCDs remain in use for legacy and precision-critical systems.

● Connectivity: Ensure your system supports the camera’s interface (e.g., CoaXPress for high data rates).

● Budget: Balance performance with system cost, including lighting, optics, and frame grabbers.

If in doubt, consult with a machine vision expert or vendor to ensure compatibility with your system design and application goals.

How many lines does a monochrome line scan camera have?

A standard monochrome line scan camera typically has one line of pixels, but some models feature two or more parallel lines. These multi-line sensors can be used to improve image quality by averaging multiple exposures, enhancing sensitivity, or capturing different lighting angles.

While single-line cameras are sufficient for most high-speed inspections, dual- and quad-line versions offer better performance in demanding environments, especially where low noise or high dynamic range is required.

To learn more about line scan technology in light-limited imaging applications, refer to our article:

Speeding up light-limited acquisition with Line Scan TDI Imaging

2025/08/07

2025/08/07