With the commercialization of 3nm technology, rising demand for AI chips, and continuous advances in mobile processors, semiconductor manufacturing has entered an era of unprecedented precision. In this environment, critical processes such as wafer defect inspection and EUV mask inspection impose ever-stricter requirements on imaging systems.

Time Delay Integration (TDI) cameras—known for high-speed scanning, large field coverage, and high-resolution imaging—have become essential components of advanced inspection equipment. Yet, their ultimate accuracy hinges on one critical factor: the correction of image non-uniformity noise.

As a leading domestic TDI camera provider, Tucsen Photonics has built strong expertise in DSNU/PRNU correction, enabling higher reliability in semiconductor inspection. This article explores the principles, evolution, and applications of DSNU/PRNU correction, and why it plays a decisive role in advanced process inspection.

Understanding DSNU and PRNU

In theory, every pixel in an image sensor should respond identically under the same conditions, whether in darkness or under illumination. In practice, slight variations in manufacturing, material inconsistencies, and readout circuitry imperfections cause pixel-to-pixel differences, resulting in fixed pattern noise (FPN).

DSNU (Dark Signal Non-Uniformity)

● DSNU occurs when pixels generate different levels of dark current in complete darkness, leading to bright or dark fixed spots, stripes, or blotches. It becomes particularly noticeable during long exposures or low-light imaging.

Figure 1-1: One of the most typical manifestations of DSNU, clearly showing the characteristics of pixel dark signal inhomogeneity.

PRNU (Photo Response Non-Uniformity)

● PRNU refers to pixel-to-pixel variations in photoelectric conversion efficiency under uniform illumination. Causes include microlens misalignment, diode size differences, and doping non-uniformity. PRNU typically manifests as brightness texture, banding, or grid-like patterns.

Figure 1-2: One of the most typical manifestations of PRNU, clearly showing the characteristics of pixel photoresponse non-uniformity.

How DSNU/PRNU Correction Works

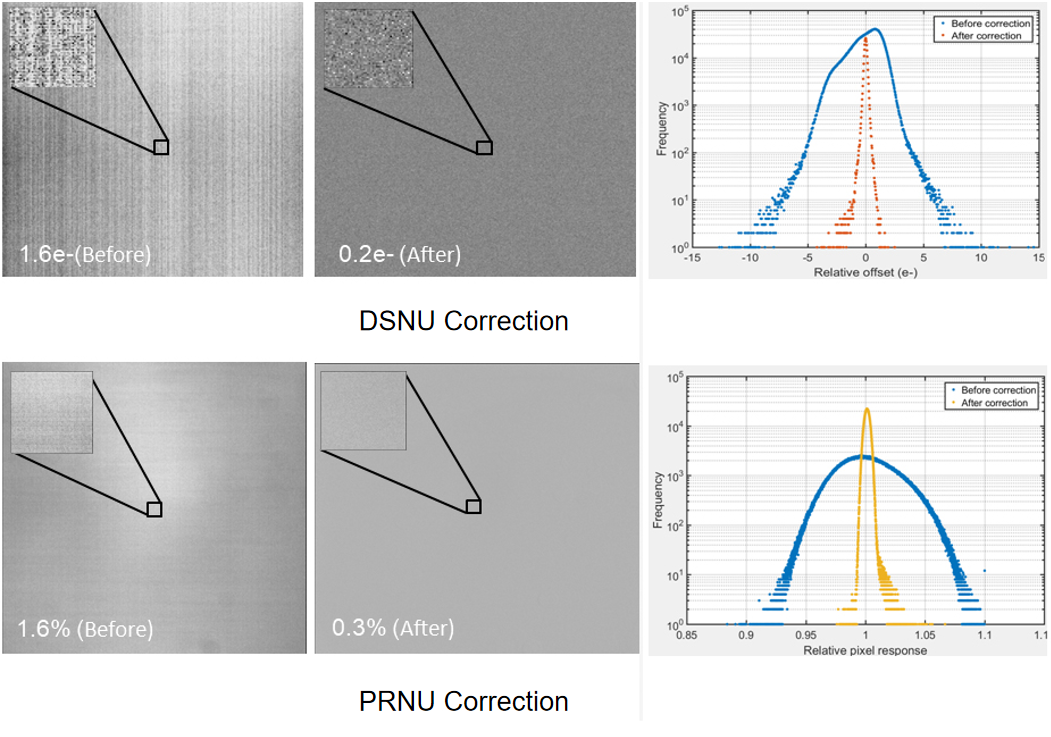

The goal of DSNU/PRNU correction is to suppress pixel individuality, making all pixels behave as though they were ideal. After correction, image backgrounds approach uniform gray, enabling higher measurement precision and data reliability.

Common approaches include:

1. Static Correction

Using dark-field and flat-field calibration data to compensate for inherent pixel differences. This method is straightforward but sensitive to temperature drift, device aging, and light source variation.

2. Cooling and Temperature-Control Correction

Using thermoelectric cooling (TEC) to suppress dark current and DSNU, combined with multi-temperature calibration profiles. This stabilizes background uniformity and ensures reliable performance over extended operation.

3. AI-Based Real-Time Correction (Emerging Trend)

Leveraging FPGA/ISP sampling with AI-driven dynamic algorithms to adjust correction coefficients in real time. This approach adapts to light fluctuations, temperature drift, and pixel aging, making it suitable for future high-throughput inspection systems.

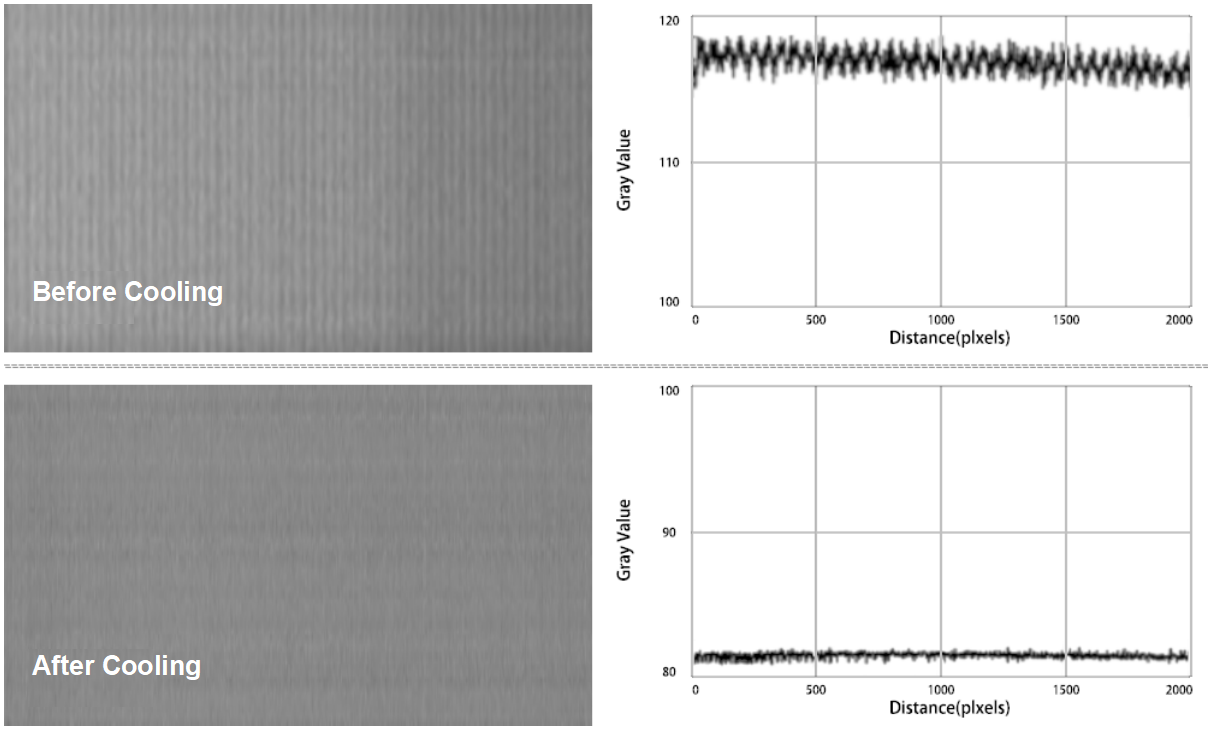

Figure 2: Comparison of DSNU/PRNU correction results before and after. After correction, the image background is highly uniform.

Technology Trends

As advanced semiconductor manufacturing processes continue to evolve and the demand for cutting-edge chips driven by AI applications keeps rising, the industry is placing higher expectations on inspection accuracy. Calibration technologies are also undergoing a shift: moving away from traditional "adjust after completion" and "process suppression" toward more intelligent, real-time calibration.

Challenges in Semiconductor Inspection

For advanced semiconductor processes, background uniformity directly determines the detectability of low-contrast defects.

● Brightfield Inspection (Low Contrast Defects)

Many wafer surface defects—such as nano-particles, lithographic residues, and micro-scratches—differ from the background by as little as 1–3%. If PRNU levels are in the same range, defect signals can be buried within background noise, leading to missed detections.

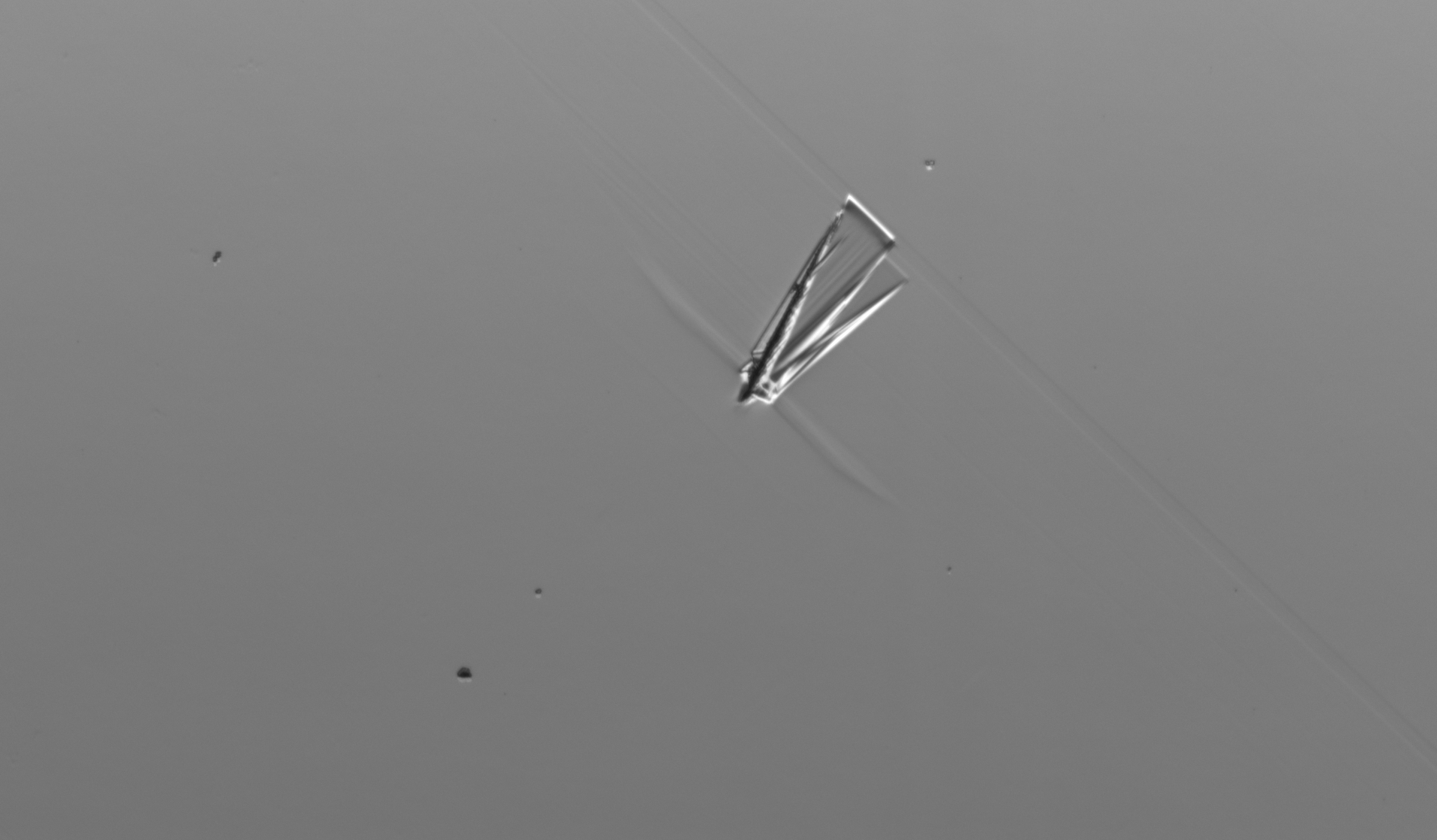

Figure 3-1: Example of Semiconductor Inspection Image under DIC Brightfield Mode

● Darkfield or Low-Light Inspection (Extremely Weak Signals)

Darkfield methods rely on weak scattered signals that may be orders of magnitude below the background. DSNU can produce false bright patterns in dark regions, easily misclassified as defects. In photoluminescence (PL) or electroluminescence (EL) testing, where signals may be only tens of electrons, even small DSNU residuals can obscure true defects.

Figure 3-2: Representative Darkfield Image of Defect Inspection in Semiconductors

● Multi-Mode Inspection (Complex Conditions)

Advanced systems often combine multiple wavelengths, angles, and line rates. However, DSNU and PRNU characteristics vary across these modes. If corrections cannot adapt dynamically, detection accuracy drops significantly in certain configurations.

Figure 3-3: Schematic Illustration of Pain Points in a Multi-Condition Semiconductor System

Tucsen’s Advanced DSNU/PRNU Correction Technology

To address these pain points, Tucsen TDI cameras employ a complete DSNU/PRNU suppression system, combining cooling, temperature control, and high-precision calibration. This ensures stable, high-accuracy inspection even across long operating times, variable modes, and low-light conditions.

1. High-Performance Cooling and Temperature Control

● Advanced TEC modules greatly reduce dark current and DSNU baseline.

● Precision thermal management keeps temperature stability within ±0.5 °C, preventing calibration drift during long-term operation.

Figure 4-1: Comparison of Background Uniformity Before and After Cooling for Tucsen's TDI Camera

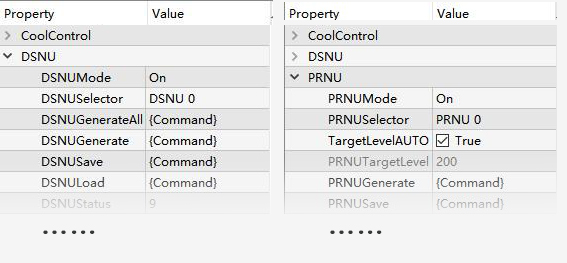

2. High-Precision Calibration

● Stores and switches among hundreds of calibration profiles to adapt to multi-wavelength, multi-angle, and multi-frequency modes.

● For example, the Gemini 8K TDI scmos camera achieves PRNU as low as 0.124% and DSNU (10-bit) at just 5.8 e⁻, sufficient to resolve defects with <1% contrast.

Figure 4-2: User Interface for PRNU/DSNU Correction in Tucsen's TDI Camera Software

Outlook: From Auxiliary to Core Technology

As semiconductor manufacturing advances, DSNU/PRNU correction has evolved from a supporting feature to a core enabler of inspection accuracy.

Tucsen Photonics continues to invest in next-generation correction technologies, focusing on higher precision, intelligent adaptation, and broader application coverage. This commitment supports both domestic self-reliance and global competitiveness in semiconductor manufacturing.

With growing demand from AI, IoT, and autonomous driving, inspection accuracy requirements will only rise further. Companies that master fundamental correction technologies will hold the advantage in driving progress across the semiconductor industry.

Contact Us

For detailed specifications, application cases, or customized solutions for Tucsen's TDI cameras, please contact our technical team. We provide full support from solution design to production line integration.

Want to learn more? Take a look at related articles:

TDI Cameras 101: What They Are and How They Work

Why TDI Camera Technology Is Gaining Ground in Industrial Imaging

Tucsen Photonics Co., Ltd. All rights reserved. When citing, please acknowledge the source: www.tucsen.com

2025/09/17

2025/09/17