sCMOS technology is rapidly being adopted across industrial and biomedical high-throughput imaging platforms. In industrial inspection, for example, TDI-sCMOS line-scan architectures have become the mainstream solution for demanding applications such as semiconductor inspection, thanks to their continuous scanning capability, high throughput, and excellent signal-to-noise performance.

However, in biomedical high-throughput imaging, line-scan architectures often fall short due to platform size constraints, highly variable sample types, and the need for precise mosaic stitching. The market urgently needs an area-scan scientific camera that delivers TDI-level throughput while maintaining the sensitivity advantages required for low-light biological samples—paving the way for the next generation of advanced biomedical imaging systems.

The Leo 5514 Pro, built on a new-generation BSI sCMOS sensor with a true global shutter architecture, achieves breakthroughs not only in throughput but also in high-speed dynamics and low-light sensitivity. Since its release, it has drawn strong attention from both research institutions and industry users, and is widely regarded as a leading force in next-generation high-throughput area-scan imaging.

This article analyzes the core requirements of biomedical high-throughput imaging systems and explains how the Leo 5514 Pro advances key technologies—including large sensor format, high sensitivity, global shutter, high frame rate, and 100G CoF high-speed data transmission—to provide valuable guidance for system architects, component selection, and high-throughput experimental workflows.

Why Large Sensor Format Is a Critical Metric?

In biomedical high-throughput imaging systems, exposure times are often relatively long. In these scenarios, tiled area imaging yields higher efficiency than continuous line-scan methods—especially in microscope-based systems where the sample remains stationary. The field of view (FOV) directly determines acquisition efficiency.

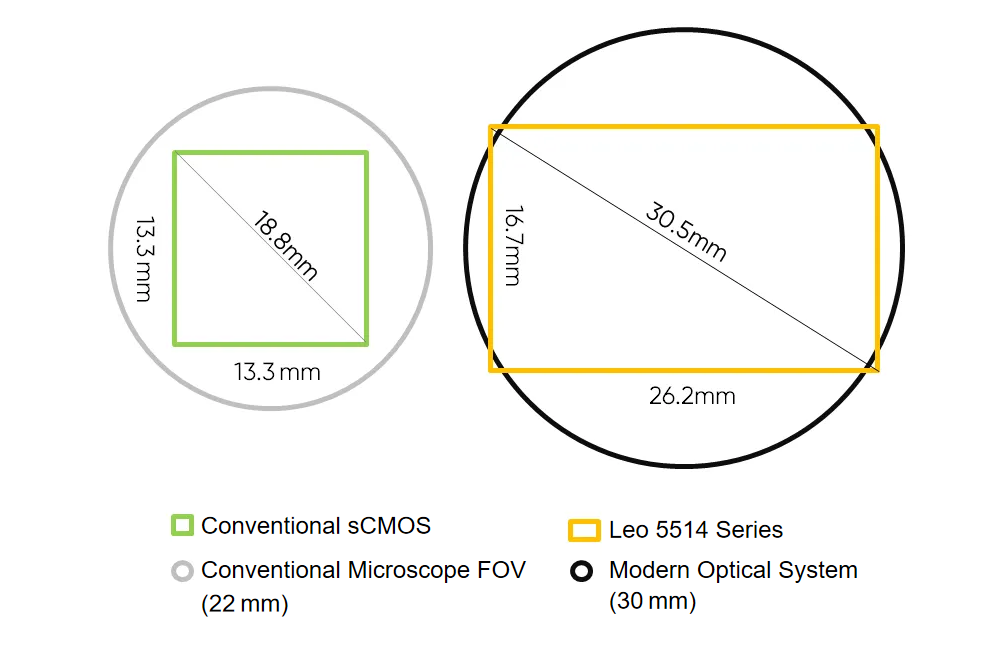

Figure 1. Comparison of Typical Optical Systems and Imaging FOV

Modern high-end microscopes have expanded their imaging FOV from 18 mm to 26 mm, with custom optical systems reaching up to 30 mm. The Leo 5514 Pro provides a 30.5 mm sensor diagonal, fully covering advanced microscope FOVs while leaving headroom for next-generation optical designs.

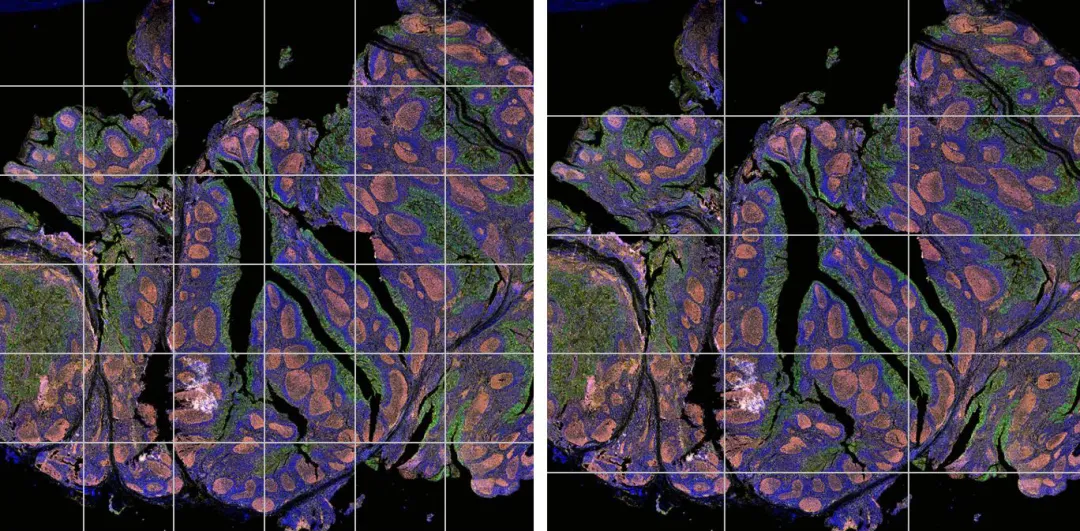

Figure 2. Example of Mosaic Stitching Counts at Different Imaging FOV

For large-sample mosaic imaging—such as whole-slide tissue sections—the Leo 5514 Pro reduces stitching cycle counts by ~60% compared with typical 6.5 μm sCMOS cameras, boosting overall throughput by nearly 2.5×.

What Does 670 fps @ 14 MP Really Mean?

In high-throughput imaging platforms, higher frame rates translate directly into higher sampling capacity per unit time, thus increasing system-level throughput.

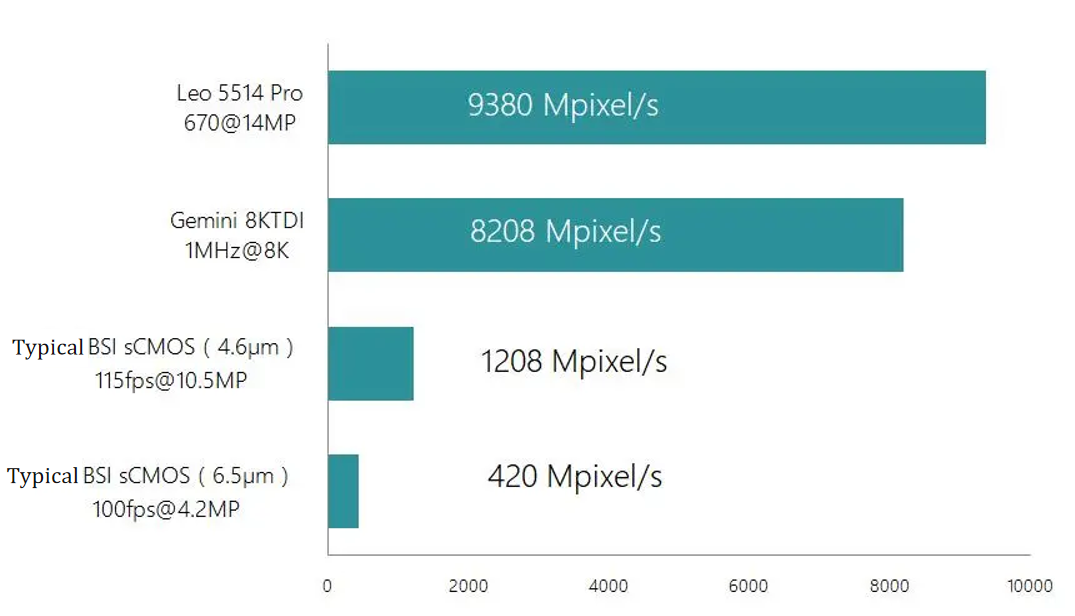

Conventional sCMOS cameras typically achieve ~100 fps at full resolution, with maximum throughput usually below 1500 Mpixel/s. In contrast, the Leo 5514 Pro reaches 670 fps at full 14 MP resolution, delivering an exceptional 9380 Mpixel/s throughput.

This represents:

● 22× the throughput of traditional sCMOS

● Performance levels surpassing even advanced TDI systems such as the Gemini 8K TDI

It stands as a true high-throughput performance benchmark.

The Real Value of a Back-Illuminated Global Shutter Architecture

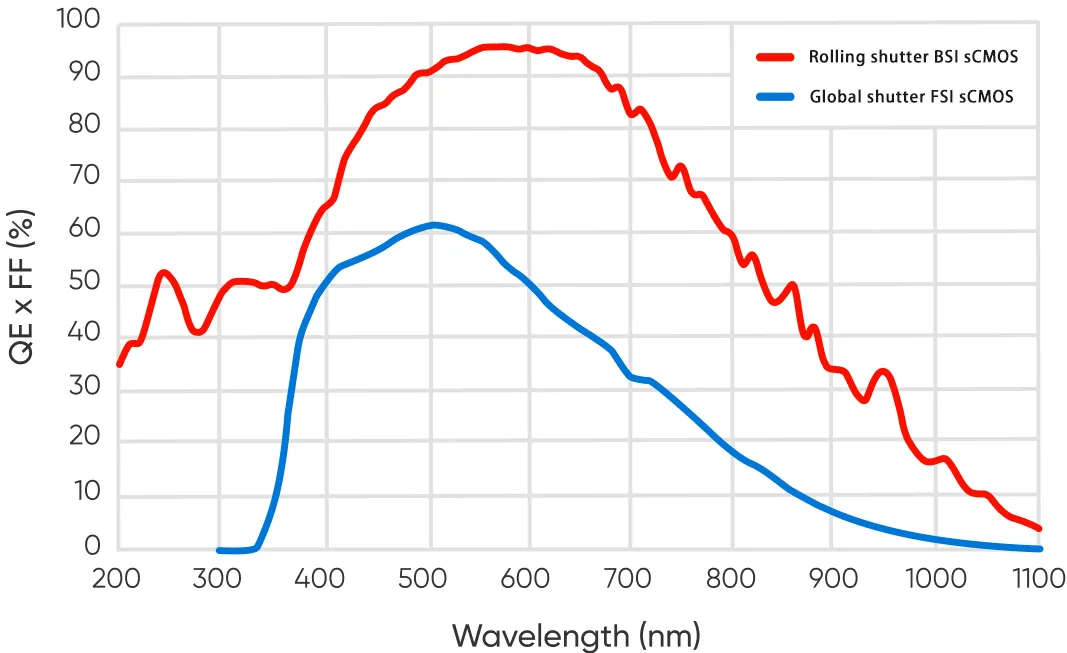

A global shutter enables simultaneous exposure without motion artifacts or geometric distortion—making it ideal for high-throughput dynamic imaging. However, implementing a scientific-grade global shutter is significantly more challenging than rolling-shutter designs.

i) Sensor-level challenges

Global-shutter pixels require additional charge-storage nodes and controlling transistors. This increases design complexity, introduces additional noise sources, and historically limits sensitivity—one of the main reasons most BSI sensors in the market still rely on rolling shutter architectures.

ii) Camera-level challenges

Even with a strong sensor foundation, achieving scientific-grade global-shutter performance requires comprehensive optimization across the entire imaging chain:

● Low-noise, high-bandwidth readout circuitry

● Thermal management and heat-isolation structures

● Power regulation and timing synchronization

● Pixel-level gain calibration and image-uniformity correction

The true value of the Leo 5514 Pro is not merely its ability to “expose faster,” but its ability to maintain quantitative scientific imaging accuracy under high-speed conditions.

With innovations spanning the sensor and full camera system—including high-speed low-noise electronics, efficient cooling, multi-channel synchronous readout control, and pixel-wise calibration—the Leo 5514 Pro meets the stringent requirements of scientific and medical imaging, achieving a stable balance between throughput and quantitative precision.

Sensitivity: A Non-Negotiable Requirement in Biomedical High-Throughput Imaging

Biomedical high-throughput samples—transparent tissues, low-fluorescence live cells—often emit extremely weak signals. High sensitivity directly improves SNR, shortens exposure time, and increases throughput, while protecting sample viability and data integrity.

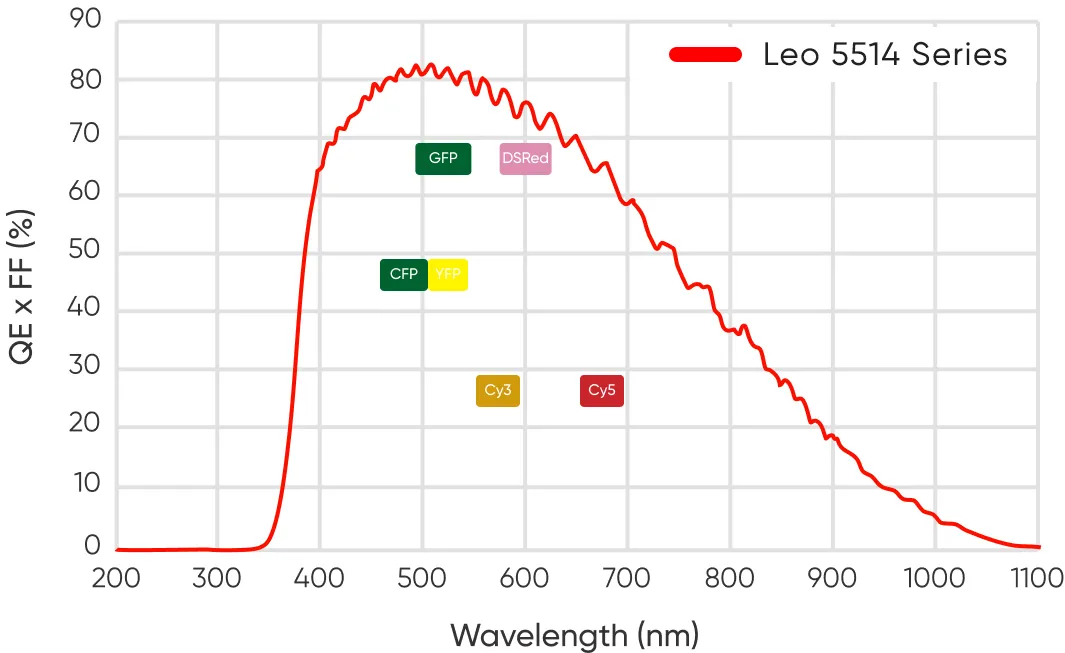

Despite its breakthroughs in speed and resolution, the Leo 5514 Pro delivers outstanding sensitivity:

● Quantum efficiency up to 83%

● Read noise as low as 2.0 e-

This places the camera among the top tier of high-sensitivity scientific imaging systems and enables reliable acquisition across a wide range of fluorescence-based high-throughput applications.

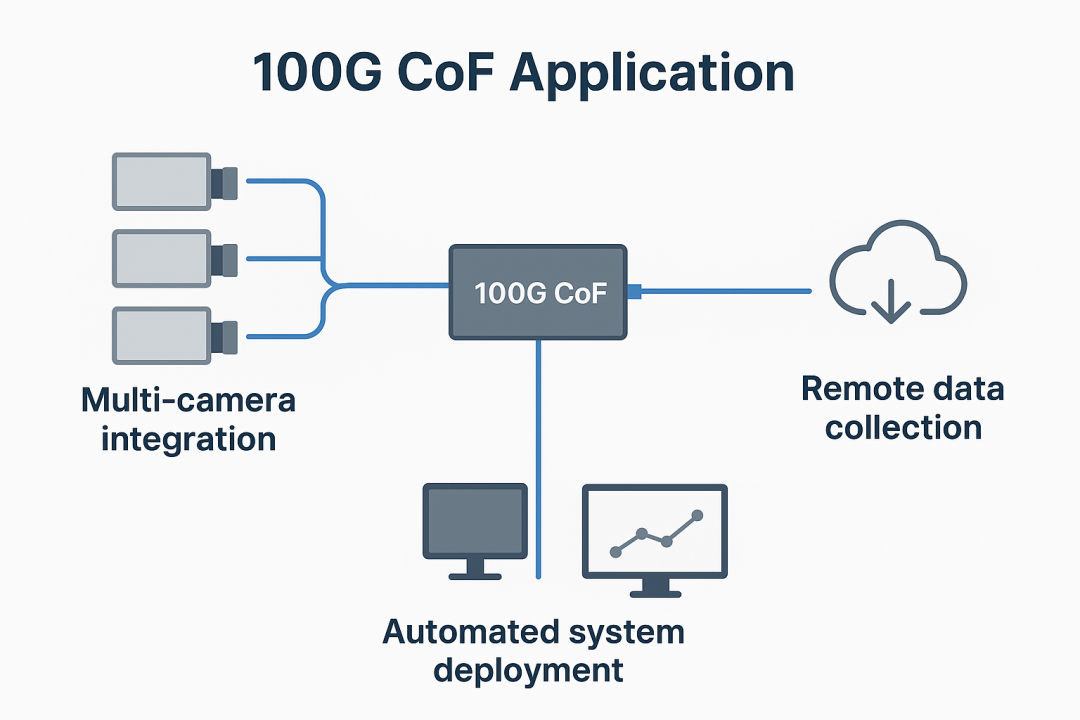

The Significance of the 100G CoF Interface Extends Beyond Speed

Modern high-throughput systems require massive data bandwidth, multi-camera synchronization, and future-proof integration for remote AI processing and large-scale automation.

The 100G CoF interface empowers these systems by providing:

i) High bandwidth

Up to 100 Gbps, ensuring real-time, lossless high-throughput data streaming.

ii) Optical-fiber transmission

Reduced EMI/EMC interference, enabling deployment in remote labs and large automated imaging platforms.

iii) Low latency and system scalability

Stable latency and ample bandwidth support future expansion into multi-channel, multi-camera, and AI-driven imaging workflows.

Thus, 100G CoF is not just a high-speed data port—it is the foundational technology enabling long-term scalability, system reliability, and intelligent integration.

The Milestone Significance of the Leo 5514 Pro

A large sensor format, high sensitivity, true global shutter, ultra-high frame rate, and a 100G CoF interface together form the core competitive strength of the Leo 5514 Pro. More importantly, these capabilities represent not a simple stack of specifications, but a meaningful breakthrough in system-level integration, addressing the long-standing trade-offs among throughput, precision, and system flexibility.

With its 30 mm+ imaging area, high-speed global-shutter imaging, scientific-grade quantitative accuracy, and scalable high-bandwidth interface, the Leo 5514 Pro overcomes limitations of traditional line-scan approaches and provides a viable upgrade path for next-generation biomedical high-throughput imaging platforms.

It represents a new technological height for scientific cameras—an essential driving force behind the evolution of high-throughput bioimaging, marking a crucial milestone as advanced research instrumentation moves toward higher throughput and greater intelligence.

Final Thoughts

The choice between TDI and area-scan architectures is not strictly industry-dependent. Whether you work in industrial inspection or biomedical imaging, optimal selection depends on sample characteristics, system design, and throughput requirements.

If you are designing a high-throughput imaging platform, Tucsen’s technical team can provide in-depth guidance on system architecture and camera selection. Please contact us for further technical consultation or application support.

Tucsen Photonics Co., Ltd. All rights reserved. When citing, please acknowledge the source: www.tucsen.com

2025/12/05

2025/12/05